Lean Shipping: Better All The Time

Hosted at Robinson Nursery, McMinnville Oregon

Lean principles apply to every type of organization, not just manufacturing. Using effective process improvement methods, the Peters Company helped Robinson Nursery create better lean shipping in their operation.

Robinson Nursery is a premiere grower of Bareroot Shade/Ornamental Trees and Shrubs, and we’re proud to post this case study published in their October 2018 newsletter.

Better All The Time

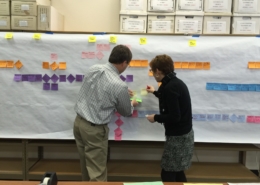

“In September, we had the opportunity to partner with The Peters Company and perform a Lean kaizen event in our container yard. Our specific focus was the process of pulling and preparing trees for shipping.

Our innovative group of problem solvers included those who have been a part of the plant pulling process for years. Key team members, supervisors, managers, and office staff helped dissect the process, identify issues and create a better system. Everyone was eager to jump in looking for ways to eliminate waste, add value, and eradicate inconsistency.

If you have been following the Lean transformation of Robinson Nursery it is likely you have become familiar with the formula for improving a process. The journey of a plant was mapped; from being pulled out of production to being loaded on the shipping truck. The steps that added value to the product were identified and we began looking for ways to eliminate the rest. The team discovered that much of their frustration came from batch processing, poor communication, and unclear standard work.

Netting machines are now moved to the bed where the plants are pulled. One piece flow eliminates wasted motion, traffic jams, and over processing. The logistics of the new process were throughly mapped out and standard work was created to properly train the rest of the crew. This guarantees fewer defects and significantly boosts consistency.

Three days were dedicated to this event. Prior to this event, it took three days to process a full truck order, about 3200 trees. That same order can now be done in about a day and a half with greater accuracy and less strain on the team.”

Lean Shipping: Value to Robinson Nursery

See this newsletter on the Robinson Nursery web site here.